Breakout Junction Boxes

Product Overview

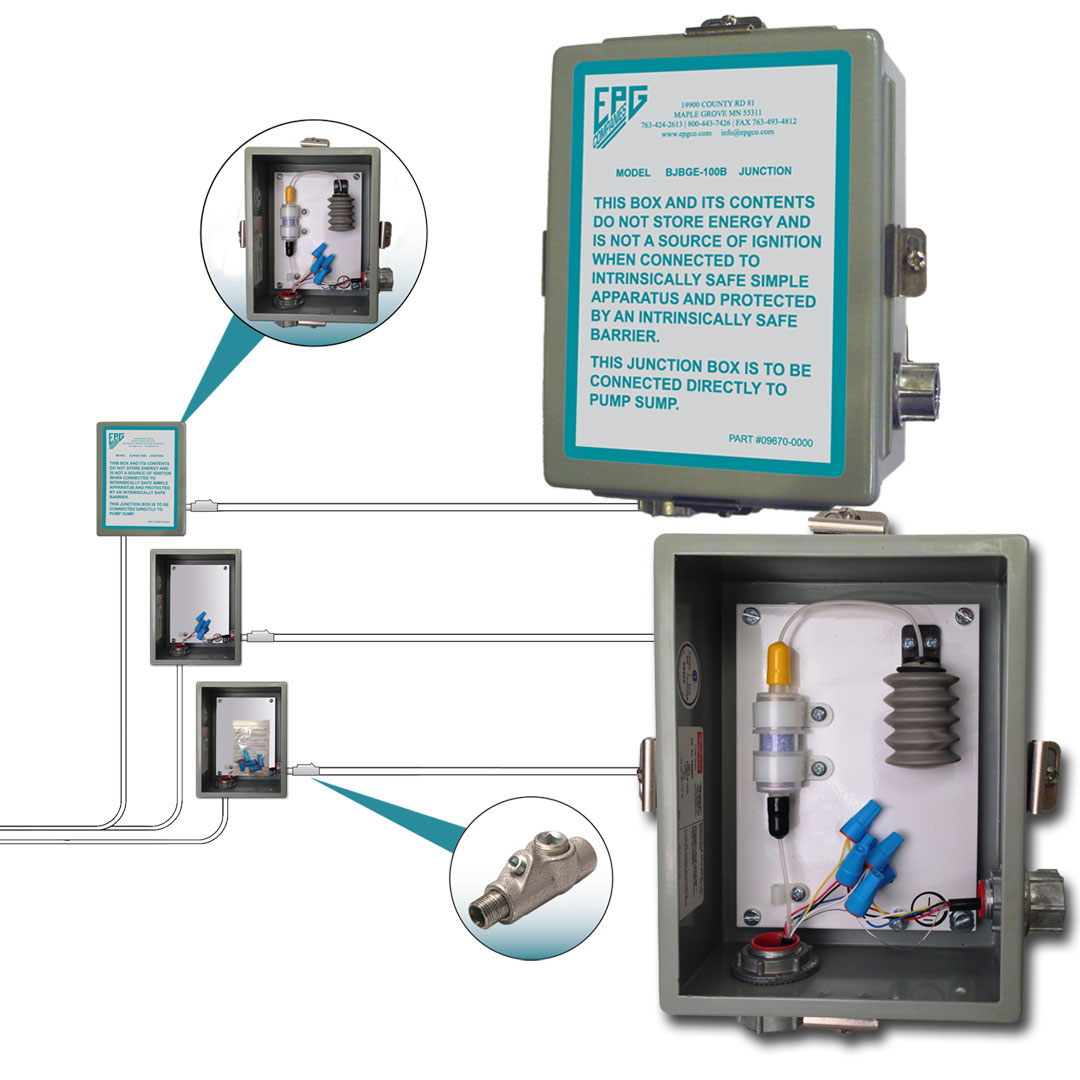

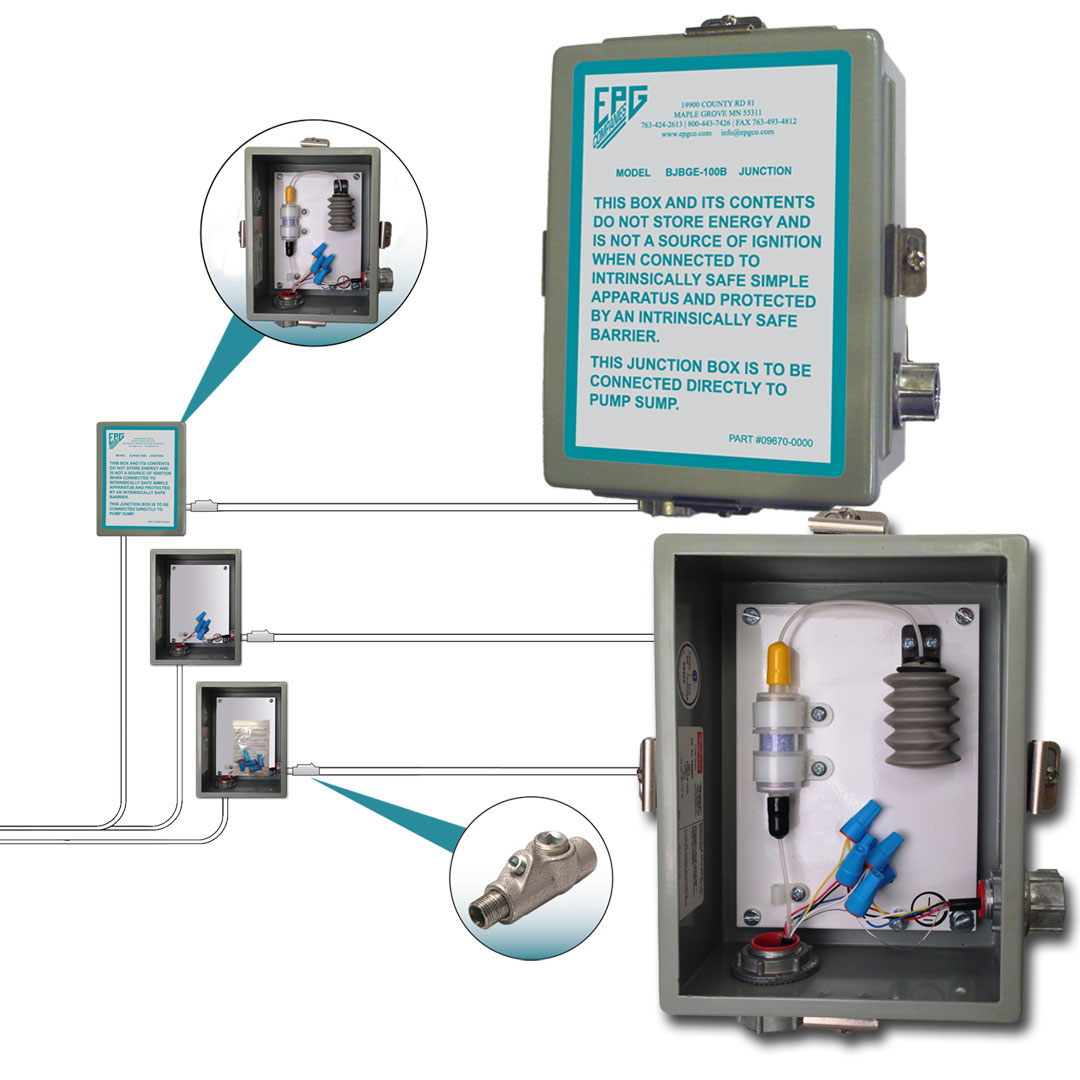

ZIRCO is the official EPG Companies representative for Western Canada, providing Breakout Junction Boxes that protect control systems from harmful gas migration and moisture damage. These essential accessories create a gas-tight seal between your riser, well, or sump and your control panel.

Landfill gases migrating through motor and sensor cable conduit to the controller is one of the largest contributors to early control panel failure. EPG Breakout Junction Boxes minimize this risk while simplifying maintenance and repair procedures.

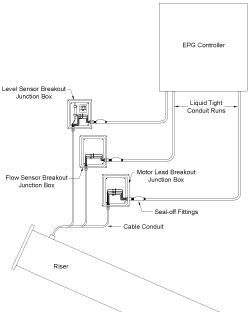

Available in NEMA 4X (non-metallic or powder coated steel), NEMA 4X stainless steel, and NEMA 7/4 explosion-proof configurations to match your specific application requirements.

Key Benefits

Seals off harmful migrating gas - Prevents methane gas and moisture from reaching control panels

Equipped with FNPT waterproof exit hub - Reliable waterproof connection point

Minimizes cable costs - Run shorter motor or sensor cable from riser to breakout box

Available in variety of configurations - Models for one or more devices including floats, level sensors, flow sensors, and temperature sensors

Weatherproof NEMA4X enclosure - Includes dryer tube and bellows to seal out moisture (level sensor models)

Technical Specifications

Available Enclosure Types

-

fiber_manual_record

Standard Models: NEMA 4X (Non-Metallic)

-

fiber_manual_record

BJBGE-100B: NEMA 4X (Powder Coated Steel)

-

fiber_manual_record

Also Available: NEMA 4X (Stainless Steel), NEMA 7/4 (Explosion-proof/weathertight)

-

info

Each level sensor includes a desiccant dryer and bellows mounted inside the enclosure

Model Number Configuration

| Model Number | Description |

|---|---|

| BJBGE-100B | Landfill Gas Effect |

| BJBD100 | Leak Detection |

| BJBF400 | Float |

| BJBF425 | Two (2) Floats |

| BJBF440 | Three (3) Floats |

| BJBF450 | Four (4) Floats |

| BJBF460 | Five (5) Floats |

| BJBF700 | Flow Sensor |

| BJBF725 | Two (2) Flow Sensors |

| BJBF750 | Three (3) Flow Sensors |

| BJBS470 | Four (4) Temperature Sensors |

| BJBL600B | Level Sensor* |

| BJBL600BT | Level Sensor* (Tank Gauging) |

| BJBL600BVA | Level Sensor* (Vacuum Application At Riser) |

| BJBL625B | Two (2) Level Sensors* |

| BJBO800B | Level Sensor & Flow Sensor* |

| BJBO800BT | Level Sensor & Float* (Tank Gauging) |

| BJBO815B | Level Sensor & Float* |

| BJBO825B | Two (2) Level & One (1) Flow Sensor* |

| BJBO850B | One (1) Level & Two (2) Flow Sensors* |

| BJBO900B | Two (2) Level & Two (2) Flow Sensors* |

| BJBO905B | Level Sensor, Flow Sensor & Leak Detection Sensor* |

| BJBO925B | Two (2) Level & Two (2) Leak Detection Sensors* |

| BJBP300 | Two (2) Probes |

| BJBP315 | Three (3) Probes |

| BJBP325 | Four (4) Probes |

| BJBP500 | Motor Lead (14 to 10 AWG) |

| BJBP500KSB | Motor Lead (KSB Motor) |

| BJBP500SP | Motor Lead (Large Cables) |

| BJBP525 | Two (2) Motor Leads (14 to 10 AWG) |

| BJBP550 | Three (3) Motor Leads (14 to 10 AWG) |

* Each level sensor includes a desiccant dryer and bellows mounted inside the enclosure.

Ready to Serve Your Industry?

Contact our team today to discuss how ZIRCO can provide specialized solutions for your industry needs with expertise spanning over 40 years of service across Western Canada.