Circulation In-Line Heaters

Circulation In-Line Heaters Overview

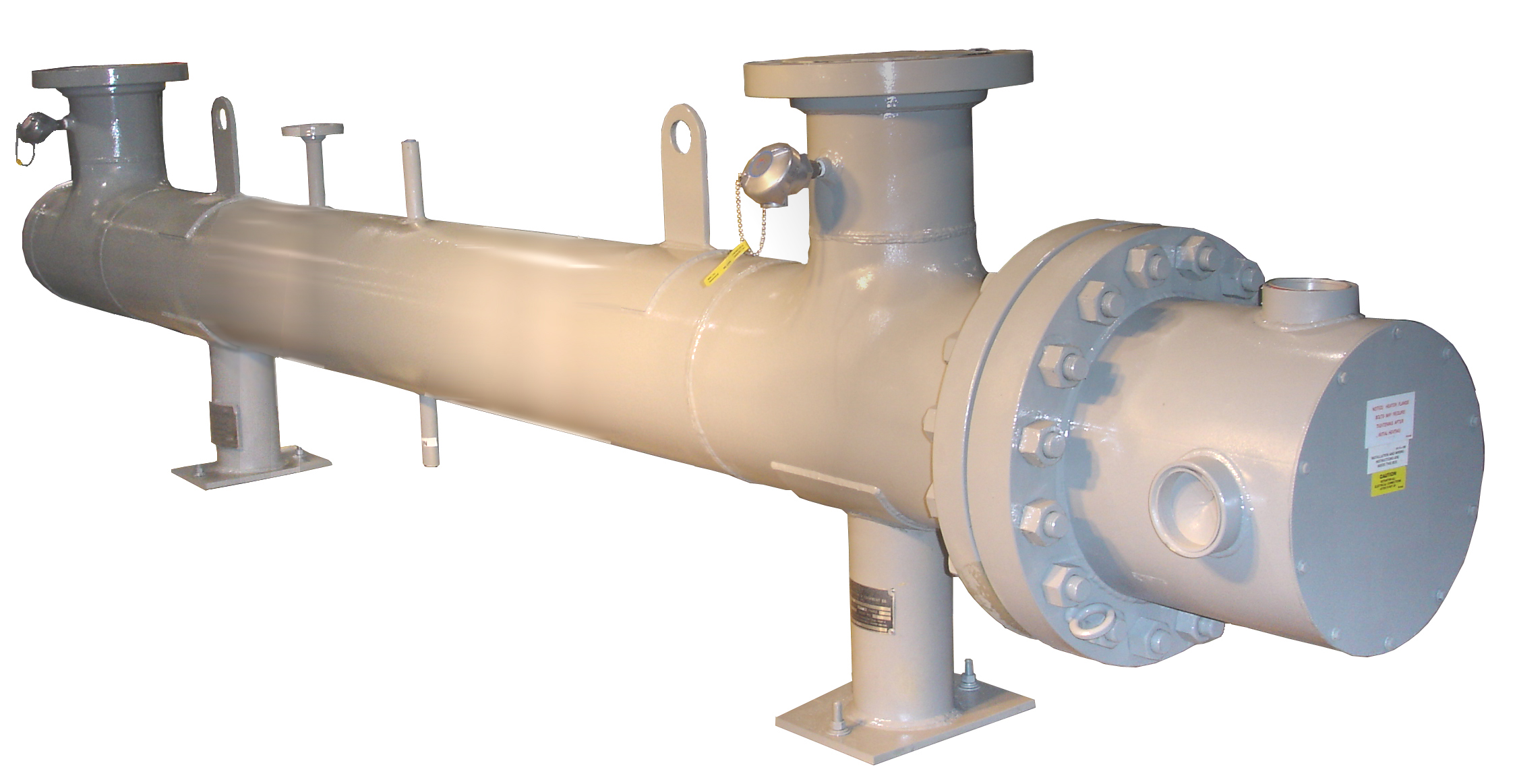

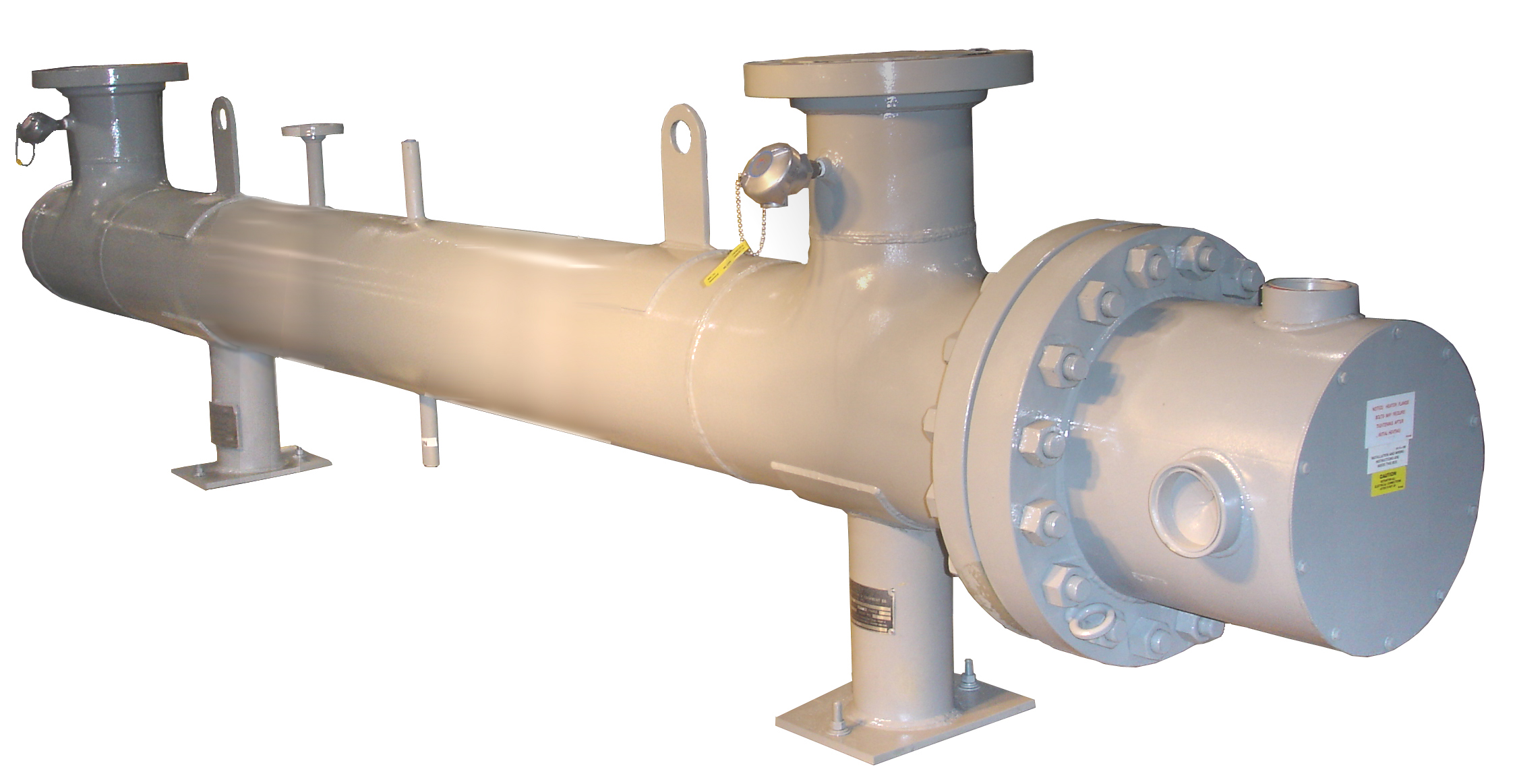

ZIRCO is proud to distribute INDEECO circulation in-line heaters as the official representative for Western Canada. These heavy-duty flow-through heaters are designed to maintain, raise, preheat, or boost temperatures of liquids and gases in process lines. With operating temperatures ranging from -50°F to 1200°F (-45°C to 649°C) and power ratings up to 50 kW, they deliver reliable performance in the most demanding industrial applications throughout Alberta's oil & gas, petrochemical, and processing industries.

Built in the USA with over 90 years of American manufacturing expertise, INDEECO circulation heaters feature heavy-duty pressure vessel construction with premium resistance elements designed for long service life. The flow-through in-line design ensures efficient heat transfer while minimizing pressure drop. Available with carbon steel or stainless steel construction, these heaters accommodate a wide variety of process fluids including water, oils, gases, steam, and specialized chemicals. Flanged and threaded connections provide flexible installation options for new or retrofit applications.

INDEECO's ISO 9001:2015 certified quality system ensures consistent manufacturing excellence. These heaters are UL Listed, CSA Certified, and NEC compliant for safe operation in hazardous and non-hazardous locations. With voltage options from 120V to 600V (single and three-phase) and 1-3 heating stages with staggered control, ZIRCO provides expert application support to help you select the right circulation heater configuration for your specific process requirements. Backed by 90+ years of American manufacturing experience, INDEECO circulation heaters deliver proven reliability for Western Canada's industrial sector.

Why Choose INDEECO Circulation In-Line Heaters?

Extreme Temperature Range

Operating temperatures from -50°F to 1200°F (-45°C to 649°C) accommodate cryogenic applications through high-temperature processes. Precision temperature control maintains setpoints within tight tolerances for consistent product quality in demanding industrial environments.

High Power Capacity

Power ratings available up to 50 kW for rapid heating and high-flow applications. Multiple voltage options from 120V to 600V support single and three-phase electrical systems. 1-3 heating stages with staggered control provide precise temperature modulation and energy efficiency.

Made in USA Quality

Over 90 years of American manufacturing experience ensures proven reliability and consistent quality. ISO 9001:2015 certified manufacturing processes deliver heaters built to exacting standards. Heavy-duty pressure vessel construction with premium resistance elements designed for long service life in harsh industrial environments.

Efficient Flow-Through Design

In-line flow-through configuration maximizes heat transfer efficiency while minimizing pressure drop in process lines. Direct heating of circulating fluids eliminates thermal lag and improves temperature response. Compact design integrates easily into existing piping systems without requiring additional tanks or vessels.

Wide Application Range

Compatible with diverse liquids and gases including water, oils, chemicals, air, steam, and specialty process fluids. Functions include maintaining temperature, raising temperature, preheating before processes, and boosting temperature in lines. Ideal for oil & gas, chemical processing, food & beverage, pharmaceutical, power generation, and military/defense applications.

Certified Safe Operation

UL Listed and CSA Certified for compliance with North American safety standards. NEC compliant electrical configurations ensure safe installation and operation. Designed for hazardous and non-hazardous locations with appropriate enclosures and certifications. High-temperature insulation and rugged construction provide safe, reliable performance in industrial environments.

Technical Specifications

Performance Specifications

| Specification | Range/Options |

|---|---|

| Temperature Range | -50°F to 1200°F (-45°C to 649°C) |

| Power Rating | Multiple ratings available up to 50 kW |

| Voltage Options | 120V, 208V, 240V, 277V, 480V (single & three-phase), up to 600V |

| Heating Stages | 1-3 stages with staggered control available |

| Functions | Maintain, raise, preheat, and boost temperatures |

Construction Specifications

| Component | Details |

|---|---|

| Vessel Construction | Heavy-duty pressure vessel design |

| Heating Elements | Premium resistance elements for long service life |

| Insulation | High-temperature insulation for efficiency and safety |

| Body Materials | Carbon steel (standard), Stainless steel (optional) |

| Connection Types | Flanged and threaded options available |

| Design Standard | ASME Section VIII, Div. 1 pressure vessel code (where applicable) |

Certifications & Compliance

| Certification | Details |

|---|---|

| Quality System | ISO 9001:2015 certified |

| Safety Certifications | UL Listed, CSA Certified |

| Electrical Compliance | NEC compliant (National Electrical Code) |

| Manufacturing | Made in USA with 90+ years experience |

| Application Areas | Hazardous and non-hazardous locations |

Typical Applications

- Industrial process heating and temperature maintenance

- Chemical processing and petrochemical applications

- Oil & gas production and refining operations

- Food & beverage processing and sanitation

- Pharmaceutical manufacturing and bioprocessing

- Power generation and utility systems

- Military & defense applications

- Water heating and steam generation

- Air and gas heating systems

- Heat transfer fluid heating

- Preheating for process equipment

- Temperature boosting in circulation lines

What Is a Circulation In-Line Heater?

A circulation in-line heater is a heavy-duty flow-through electric heater designed to heat liquids and gases directly in process piping. Unlike immersion heaters that are submerged in tanks, circulation heaters are installed in-line, allowing the process fluid to flow through the heater body where it comes into direct contact with heating elements. This design provides rapid heat transfer, precise temperature control, and minimal pressure drop in continuous flow applications.

INDEECO circulation heaters feature a heavy-duty pressure vessel containing multiple heating elements specifically designed for the required wattage and temperature rise. As fluid circulates through the vessel, heat is transferred efficiently from the elements to the process medium. The compact in-line design eliminates the need for separate heating tanks and integrates seamlessly into existing piping systems. Multiple heating stages with staggered control allow for modulated power output, enabling precise temperature maintenance without hot spots or thermal shock.

These heaters excel in applications requiring continuous temperature maintenance, rapid heating, or preheating of process fluids. Common uses include maintaining oil temperature in pipelines, heating chemical feeds before reactors, preheating fuel oils for combustion systems, boosting steam temperature in process lines, and heating water for industrial cleaning systems. ZIRCO provides expert application support for Western Canada industries, helping you select the right circulation heater configuration for your specific process requirements including flow rate, temperature rise, fluid properties, and electrical characteristics.

Product Literature & Resources

Technical Documents

Circulation Heater Complete Catalog

Full product catalog with all models, specifications, and application data

PDF - 4.8 MB

Circulation Heater Sales Sheet

Product overview with key features, specifications, and typical applications

PDF - 3.1 MB

Technical Manual (ENM-2178-01)

Detailed technical manual with installation, operation, and maintenance instructions

PDF - 404 KB

Request for Quote

Request for Quote (RFQ) Form

Download and complete this form to submit your immersion heater requirements for quotation

Duct Heater RFQ Form

Specific RFQ form for duct heater applications

Contact for More Information

ZIRCO is the authorized Western Canada representative for INDEECO circulation in-line heaters. Contact our team for:

- Technical specifications and sizing assistance

- Application engineering support

- Quotations and delivery information

- After-sales service and support

- Custom configurations for special applications

- Voltage and certification requirements

Ready to Optimize Your Process Heating?

Contact our team today to discuss how INDEECO circulation in-line heaters can provide reliable, efficient temperature control for your industrial process applications. ZIRCO provides expert support for Western Canada's oil & gas, chemical processing, food & beverage, pharmaceutical, and manufacturing industries with 90+ years of American manufacturing quality.