KFD Detonation Proof In-Line Flame Arrester

KFD Detonation Proof In-Line Flame Arrester Overview

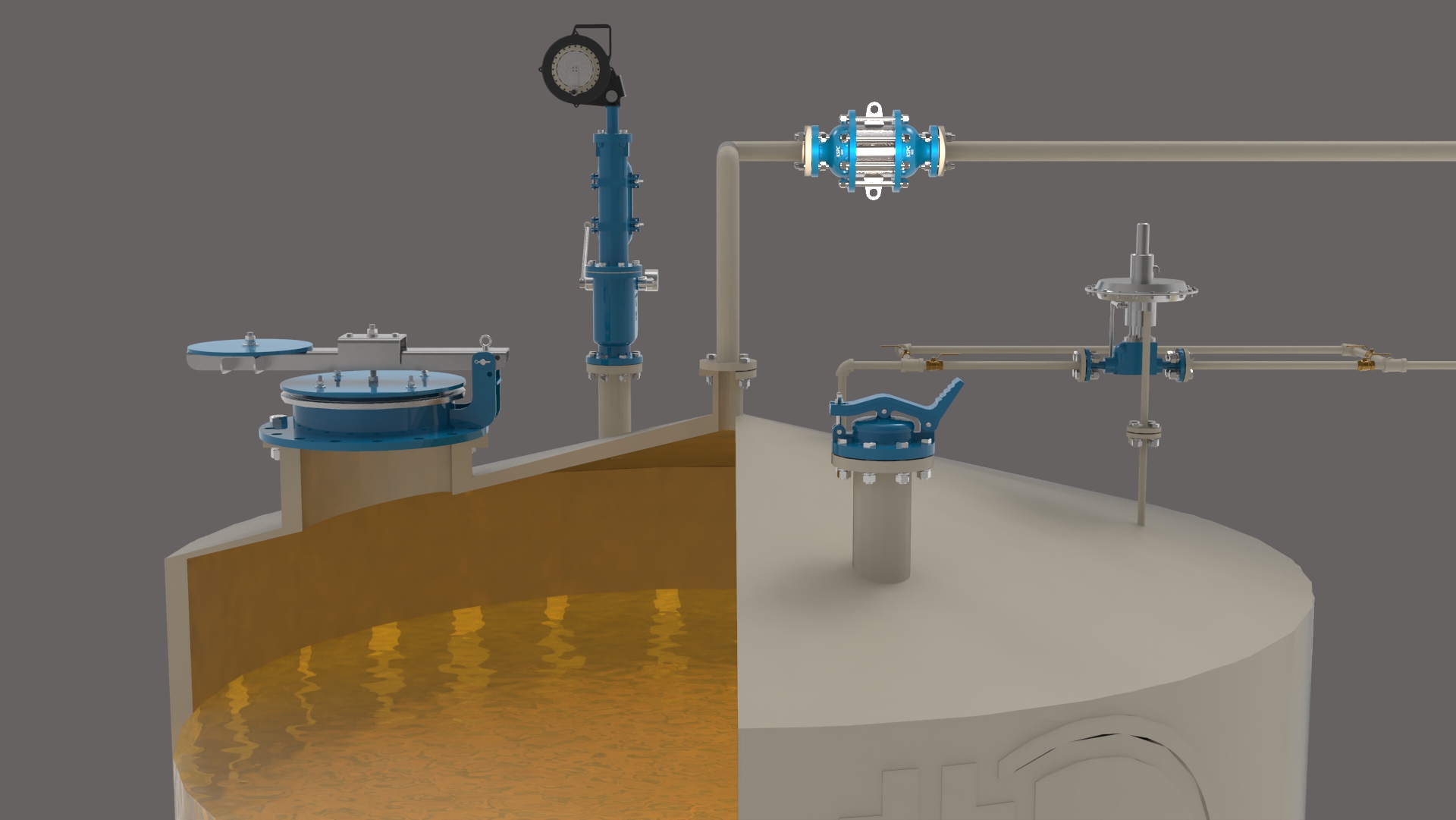

ZIRCO is proud to distribute KSPC KFD Detonation Proof In-Line Flame Arresters as the official representative for Western Canada. These advanced safety devices are designed, manufactured and tested according to the most rigorous international standards including API 2000, BS 7244, EN 12874, ISO 16852, USCG, and IMO MSC/Circ.677, providing critical flame protection for complex piping systems in industrial facilities.

The KFD represents the highest level of flame arrester technology, specifically engineered to stop flame propagation in manifolded or long-run piping systems where flame velocities can reach dangerous levels. Unlike deflagration flame arresters that only handle subsonic flame speeds, the KFD is designed to halt ignited flammable vapors at both subsonic AND supersonic velocities (detonation conditions), providing comprehensive protection for the most demanding applications.

Built by Korea Steel Power Corp. (KSPC) to the highest standards, these detonation-proof flame arresters are rated for continuous burning against the 316L stainless steel flame cell and deliver dependable performance in critical applications throughout Western Canada's oil & gas, petrochemical, and processing sectors where maximum protection is essential.

Why Choose KFD Detonation Proof In-Line Flame Arresters?

Advanced Certification

Certified to API 2000, BS 7244, EN 12874, ISO 16852, USCG, and IMO MSC/Circ.677 standards - the most comprehensive certification suite available for flame arresters, ensuring compliance for land-based and marine applications worldwide.

Detonation Protection

Engineered to stop flames at subsonic AND supersonic velocities. Unlike deflagration arresters that only handle slow-moving flames, the KFD provides comprehensive protection against high-velocity detonation events in complex piping systems.

Continuous Burning Protection

Rated for continuous burning against the 316L stainless steel flame cell, providing sustained protection even during prolonged flame exposure events. Critical for applications where flames may persist until manually extinguished.

Manifold & Long-Run Systems

Specifically designed for manifolded or long-run piping systems where flame acceleration can occur. Ideal for complex pipeline networks in refineries, chemical plants, and large-scale industrial facilities throughout Western Canada.

Premium Construction

Available with carbon steel (epoxy coated), 304SS, or 316SS housings, all featuring 316L stainless steel flame cells. Heavy-duty construction ensures long service life in harsh industrial environments and corrosive applications.

High-Performance Design

Engineered for critical applications requiring maximum protection. The KFD represents the ultimate in flame arrester technology, providing peace of mind for facilities where failure is not an option and safety is paramount.

Technical Specifications

Standards & Certifications

| Standard | Description |

|---|---|

| API 2000 | American Petroleum Institute Standard for Venting Atmospheric and Low-Pressure Storage Tanks |

| BS 7244 | British Standard Specification for Flame Arresters |

| EN 12874 | European Standard for Flame Arresters |

| ISO 16852 | International Standard for Flame Arresters - Performance Requirements, Test Methods and Limits for Use |

| USCG | United States Coast Guard Certification for Marine Applications |

| IMO MSC/Circ.677 | International Maritime Organization Standard for Flame Arrester Design and Testing |

Operating Conditions

| Parameter | Standard Range |

|---|---|

| Operating Temperature | Up to +60°C / +140°F |

| Operating Pressure | Up to 1.1 bar abs |

| Gas Group | NEC Group D or IEC IIA gases (standard) - Other gas groups available as options |

| Flame Velocity | Subsonic AND supersonic (detonation) - unlike deflagration arresters |

| Continuous Burning Rating | Rated for continuous burning against flame cell |

Size & Material Specifications

| Specification | Details |

|---|---|

| Size Range | ½" (15mm) to 12" (DN 300) |

| Housing Materials | Carbon Steel (epoxy coated), 304SS, 316SS |

| Flame Cell Element | 316L Stainless Steel |

| Standard Flanges | ANSI 150lb |

| Application Type | In-line installation for manifolded or long-run piping systems |

Design Features

| Feature | Description |

|---|---|

| Detonation Protection | Stops ignited flammable vapors at subsonic or supersonic velocities (detonation conditions) |

| System Application | Designed for manifolded or long-run piping systems where flame acceleration can occur |

| Flame Cell Construction | 316L stainless steel matrix engineered to quench flames through heat absorption |

| Continuous Burning | Rated for continuous burning against the flame cell element |

| Marine Certification | USCG and IMO certified for marine and offshore applications |

Typical Applications

- Manifolded piping systems in oil & gas processing facilities

- Long-run vapor recovery and collection lines

- Petrochemical plant complex piping networks

- Chemical processing pipelines throughout Western Canada

- Refinery manifold and distribution systems

- Marine and offshore loading systems (USCG/IMO certified)

- Storage tank farm manifold piping

- Critical fuel gas distribution systems requiring maximum protection

Maintenance Requirements

Periodic inspection and maintenance is required to ensure continued optimal performance and safety compliance. The KFD detonation-proof in-line flame arrester is designed for maintenance access to minimize downtime in critical pipeline operations.

The cell assembly can be removed for inspection and cleaning purposes. Cleaning should be accomplished using appropriate methods that do not damage the precision flame cell openings. Any deformation of the cell openings may hamper flow through the cell and reduce effectiveness.

The gaskets should be inspected regularly and replaced if necessary to maintain proper sealing and prevent bypass of the flame arrester element. Given the critical nature of detonation protection applications, ZIRCO provides comprehensive maintenance support and replacement parts for Western Canada customers.

What Is a Detonation Proof In-Line Flame Arrester?

A detonation proof in-line flame arrester is an advanced safety device installed within pipelines to prevent the propagation of flame at both subsonic AND supersonic velocities. Unlike deflagration flame arresters that only handle slow-moving (subsonic) flames, detonation flame arresters are designed to stop high-velocity detonation waves that can develop in manifolded or long-run piping systems.

Understanding the Difference: When a flame travels through a pipe, it can accelerate due to turbulence and flame front instabilities. In short pipe runs, flames typically remain at subsonic velocities (deflagration). However, in manifolded systems or long piping runs, flames can accelerate to supersonic velocities, creating a detonation wave with significantly higher energy and destructive potential.

The KFD utilizes a robust 316L stainless steel flame cell engineered to withstand and quench both deflagration and detonation flames. When a flame attempts to pass through the element, the heat is absorbed through the metal surfaces, cooling the flame below its ignition temperature and extinguishing it even at supersonic velocities.

Additionally, the KFD is rated for continuous burning against the flame cell, meaning it can sustain prolonged flame exposure without failure - a critical capability for applications where flames may persist until emergency response teams can intervene. With certifications from USCG and IMO, the KFD is suitable for both land-based industrial facilities and marine applications worldwide. ZIRCO provides expert application support to help determine if your system requires detonation-level protection.

Deflagration vs Detonation: Which Do You Need?

| Factor | Deflagration Arrester (KSFI/KSFE) | Detonation Arrester (KFD) |

|---|---|---|

| Flame Velocity | Subsonic only (slow-moving flames) | Subsonic AND supersonic |

| Application | Simple pipe runs, vent pipes, end-line applications | Manifolded or long-run piping systems |

| Cost | Lower cost for standard applications | Higher cost for advanced protection |

| Certifications | API 2000, BS 7244, EN 12874, ISO 16852 | All above PLUS USCG, IMO |

| Continuous Burning | Not typically rated | Rated for continuous burning |

| When to Use | Standard applications with short pipe runs | Critical applications with complex piping |

Contact ZIRCO for expert guidance on selecting the appropriate flame arrester for your specific application.

Product Literature & Resources

Technical Documents

KFD Detonation Proof In-Line Flame Arrester Product Brochure

Complete specifications, dimensions, performance data, and application guidelines for KFD Detonation Proof In-Line Flame Arresters

Request for Quote

Request for Quote (RFQ) Form

Download and complete this form to submit your flame arrester requirements for quotation

Contact for More Information

ZIRCO is the authorized Western Canada representative for KSPC KFD Detonation Proof In-Line Flame Arresters through Secure Enviro Systems. Contact our team for:

- Technical specifications and application guidance

- Deflagration vs detonation assessment

- System evaluation and sizing assistance

- Quotations and delivery information

- After-sales service and maintenance support

- Custom configurations for special applications

- Compliance with Canadian and international safety regulations

Ready to Protect Critical Pipeline Systems?

Contact our team today to discuss how KSPC KFD Detonation Proof In-Line Flame Arresters can provide maximum protection for your manifolded and long-run piping systems. ZIRCO provides expert application support to help you determine if your facility requires detonation-level protection, serving Western Canada's oil & gas, petrochemical, and processing industries through Secure Enviro Systems.