Gas Compression

Gas Compression Overview

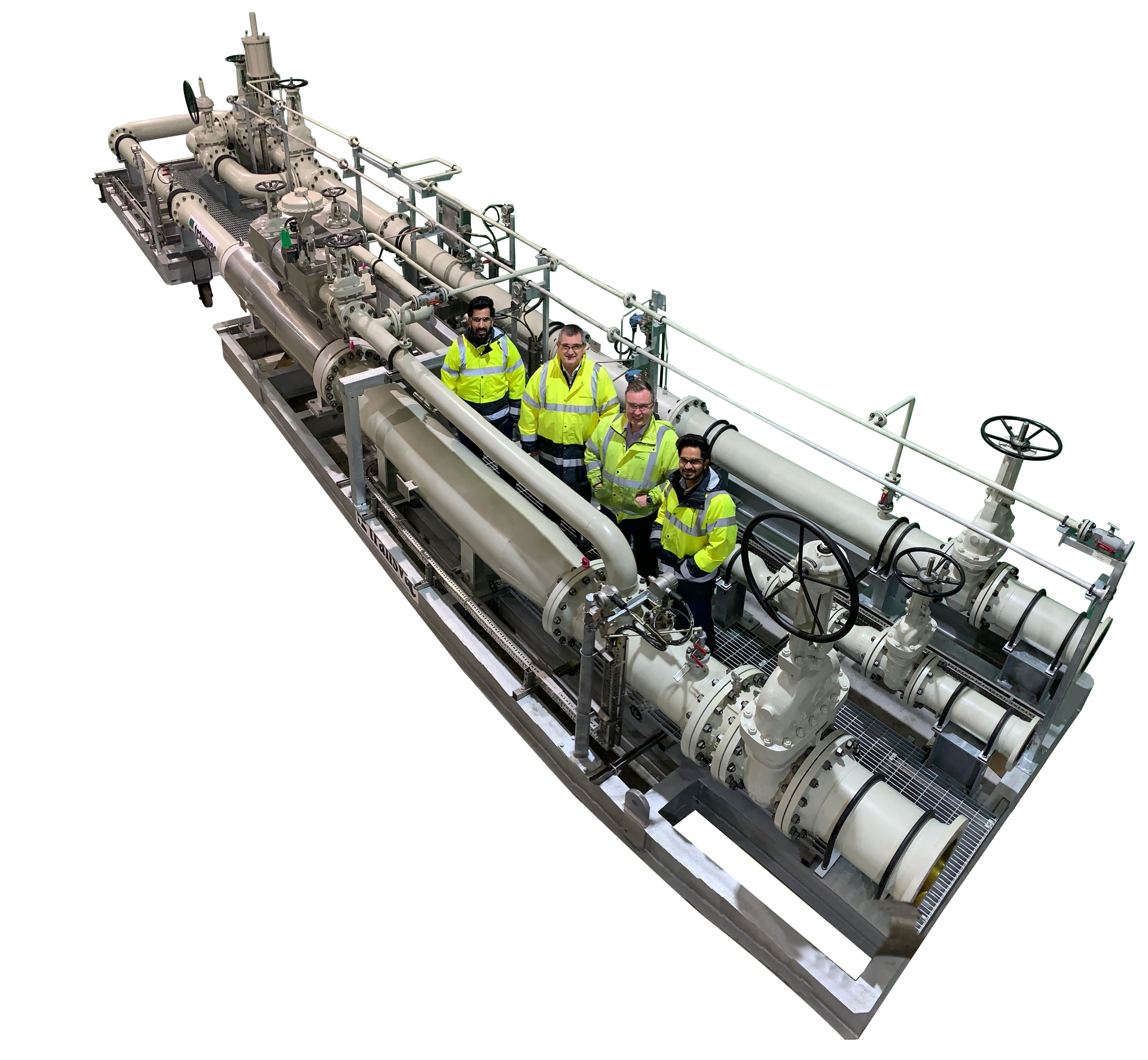

Transvac Gas Compression Ejectors are the most reliable gas compressors available, offering static, pipework-based compression with no moving parts and zero maintenance requirements. Unlike traditional mechanical compressors, ejectors use available energy from high-pressure motive streams to compress gas, providing unmatched reliability and minimal operational costs.

Key Advantages: Ejectors can handle gas compression with up to 2% liquid by volume, making them ideal for challenging oil and gas applications. Two-stage ejector sets can achieve higher compression ratios for demanding process requirements. ZIRCO brings these innovative solutions to Western Canada's oil and gas sector.

Applications: Gas compression ejectors are commonly used for CO2 injection, water injection, gas injection, enhanced oil recovery, and gas boosting applications. Their static design makes them particularly suitable for remote locations and harsh environments where maintenance access is limited.

Why Choose Ejector Technology?

No Moving Parts

Static, pipework-based compressors with no rotating components or mechanical seals. Zero maintenance means minimal downtime and lower lifecycle costs.

Cost Effective

Utilize existing or waste energy for operation. No new power requirements when high-pressure motive streams are available, dramatically reducing operating expenses.

Highly Reliable

Simple design with no components to wear, fail, or replace. Operates continuously without scheduled maintenance, ideal for remote and critical applications.

Technical Specifications & Design

How Gas Compression Ejectors Work

Transvac gas compression ejectors operate on the principle of utilizing a high-pressure motive fluid (gas or liquid) to entrain and compress a lower-pressure suction gas. The motive fluid passes through a nozzle, converting pressure energy into kinetic energy and creating a low-pressure zone that draws in the suction gas.

The mixed streams then pass through a diffuser, where kinetic energy is converted back into pressure, delivering compressed gas at the discharge. This simple, static design provides reliable operation without any moving parts.

Performance Capabilities

| Feature | Specification |

|---|---|

| Motive Fluid Options | Gas or Liquid driven ejectors available |

| Liquid Tolerance | Can handle up to 2% liquid by volume |

| Multi-Stage Capability | Two-stage ejector sets for higher compression ratios |

| Construction Materials | Carbon steel, stainless steel, and exotic alloys available |

| Pressure Ratings | Custom designed for application-specific requirements |

| Temperature Range | Designed for cryogenic to high-temperature applications |

| Maintenance Requirement | Zero moving parts = zero scheduled maintenance |

Motive Fluid Options

Gas Motivated Ejectors

Utilize high-pressure gas streams such as compressor discharge, export gas, or gas recycle as the motive fluid. Ideal when high-pressure gas is readily available and no downstream phase separation is required.

Liquid Motivated Ejectors

Use high-pressure liquid streams like produced water, injection water, or amine as motive fluid. Can integrate with existing pumps and separators, minimizing CAPEX for new installations.

Gas Compression Applications

Transvac gas compression ejectors serve diverse applications across the oil and gas industry, providing reliable compression solutions where traditional mechanical compressors face challenges.

CO2 Injection

Compress CO2 for enhanced oil recovery (EOR) and carbon capture and storage (CCS) applications. Ejectors provide reliable compression for CO2 flooding projects with minimal maintenance requirements.

Water Injection

Compress gas for injection into water injection systems or utilize high-pressure injection water as the motive fluid. Ejectors can integrate with existing water injection infrastructure for cost-effective gas handling.

Gas Injection for Enhanced Recovery

Compress and inject gas for enhanced oil recovery operations. Ejectors handle gas injection pressures with minimal complexity, providing reliable operation for continuous injection projects.

Gas Boosting

Boost low-pressure gas streams to meet pipeline or process requirements. Ejectors provide cost-effective gas boosting for wellhead gas recovery, vapor recovery units, and gas gathering systems.

Climate Change Mitigation

Support greenhouse gas reduction initiatives through methane recovery and flare gas minimization. Ejectors enable gas recovery projects that would be uneconomical with traditional compression technology.

Western Canada Applications

ZIRCO provides Transvac gas compression ejector solutions specifically tailored for Western Canada's oil and gas industry, including:

- Oil Sands Operations: Gas compression for SAGD and CSS operations

- Conventional Oil & Gas: Wellhead gas boosting and gathering systems

- British Columbia Gas Fields: Remote gas compression where maintenance access is limited

- Enhanced Recovery Projects: CO2 and gas injection for mature field revitalization

- Gas Plant Applications: Fuel gas boosting and low-pressure gas recovery

Product Literature & Resources

Technical Documents

Request for Quote

Request for Quote (RFQ) Form

Download and complete this form to submit your ejector requirements for quotation

Contact for More Information

ZIRCO is the authorized Western Canada representative for Transvac Gas Compression Ejectors. Contact our team for:

- Technical specifications and sizing

- Application engineering support

- Quotations and delivery information

- After-sales service and support

Ready to Upgrade Your Gas Compression?

Contact our team today to discuss how Transvac Gas Compression Ejectors can provide reliable, maintenance-free compression for your oil and gas operations. ZIRCO provides expert support for Western Canada applications.