Natural Draft Burners

Product Overview

ZIRCO distributes Flameco Industries natural draft burners designed for oil and gas industry applications. These burners have been serving the industry with top-performing natural draft burners and vessel accessories for over 40 years.

Available in multiple configurations including O-Type, Hinge Type, Box Type, and Side Mount designs. Each burner can be customized with various enhancement options such as reduced noise, low noise, air control, elevated air supply, and combinations to meet specific site requirements.

ZIRCO Advantage: Local Western Canada Support

- check_circle Immediate technical support from Calgary, AB

- check_circle Quick delivery across Western Canada

- check_circle Application engineering for Alberta's oil & gas conditions

Why Choose Flameco Natural Draft Burners?

40+ Years Experience

Proven design reliability since 1980 with thousands of installations worldwide

Custom Configurations

13 design options with 10 enhancements and 9 add-ons for perfect application fit

Noise Reduction Options

Reduced Noise and Low Noise designs for community-conscious operations

Wide BTU Range

50,000 to 15,000,000 BTU/hr covering small to large applications

Multiple Mount Options

O-Type, Hinge Type, Box Type, and Side Mount configurations

Quality Assured

Manufactured to exacting standards with full technical documentation

Natural Draft Burner Types

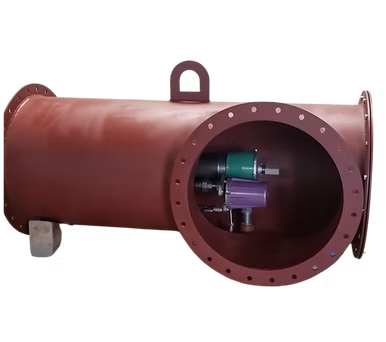

Side Mount Configuration

Recommended BTU Range

50,000 – 2,000,000 BTU/hr

Flame Cell Size Range

10” - 48”

Recommended for Firetube Sizes

4” – 30”

Recommended Use

Clearance & ease of access

O-Type Burner Specifications

Design Type

Cylindrical Standard Design

Best Applications

General Purpose

BTU Range

50,000 - 2,000,000 BTU/hr

Firetube Sizes

4" - 30" diameter

Hinge Type Burner Specifications

Design Type

Hinged Removable Design

Best Applications

Easy Maintenance Access

BTU Range

50,000 - 2,000,000 BTU/hr

Firetube Sizes

4" - 30" diameter

Box Type Burner Specifications

Design Type

Rectangular Box Design

Best Applications

Space-Constrained Installations

BTU Range

50,000 - 10,000,000 BTU/hr

Firetube Sizes

4" - 30" diameter

Typical Applications

Oil & Gas Production

Heater treaters, separator heaters, glycol reboilers

Water Treatment

Dehydration units, heat medium systems

Industrial Processing

Process heaters, thermal oxidizers, incinerators

Agricultural Operations

Grain dryers, heating systems, livestock facilities

Available Burner Types

| Type | Description | Best For |

|---|---|---|

| O-Type | Standard cylindrical design with multiple configuration options | General purpose applications |

| Hinge Type | Hinged design for easy access and maintenance | Limited access installations |

| Box Type | Rectangular enclosure design with enhanced durability | Heavy-duty applications |

| Side Mount | Side-mounted configuration for clearance requirements | Space-constrained areas |

Natural Draft Burner Designs

Current supported Natural Draft Burner Designs with multiple customization options available.

| Design | O-Type | Hinge Type | Box Type | Side Mount |

|---|---|---|---|---|

| Standard | ✓ | ✓ | ✓ | ✓ |

| Reduced Noise | ✓ | ✓ | ✓ | ✓ |

| Air Control Reduced Noise | ✓ | ✓ | ✓ | ✓ |

| Push-Pull Air Control Reduced Noise | ✓ | ✓ | ✓ | ✓ |

| Push-Pull Air Control Low Noise | ✓ | ✓ | ✓ | ✓ |

| Low Noise | ✓ | ✓ | ✓ | ✓ |

| Elevated Air Supply | ✓ | ✓ | ✓ | ✓ |

| Elevated Air Supply Reduced Noise | ✓ | ✓ | ✓ | ✓ |

| Elevated Air Supply Low Noise | ✓ | ✓ | ✓ | ✓ |

| Elevated Air Supply Rotary Air Control | ✓ | ✓ | ✓ | ✓ |

| Cam Lock | ✓ | ✓ | ✓ | ✓ |

| Air Control | ✓ | ✓ | ✓ | ✓ |

| Air Control Low Noise | ✓ | ✓ | ✓ | ✓ |

Elevated Air Supply

A safety system designed to burn off excess or unusable gases at high elevations, minimizing fire hazards.

Reduced & Low Noise

An insulated design targeted at satisfying site noise requirements. The Reduced Noise is partially insulated for cost-effectiveness, while Low Noise is fully insulated with a baffle plate for maximum noise reduction.

Air Control

A pneumatic push-pull, or rotating, system that controls the primary air flow draft. Optimizes draft through air supply while reducing start-up cycles.

Combining Designs

Engineering expertise and manufacturing capabilities enable production of various design combinations to meet customer requirements.

Natural Draft Burner Enhancement Options

Options that are included in the manufacturing design and production of the natural draft burner.

| Enhancement | O-Type | Hinge Type | Box Type | Side Mount |

|---|---|---|---|---|

| 6” x 6” Access | ✓ | ✓ | ✓ | ✓ |

| Lifting Lugs | ✓ | ✓ | ✓ | ✓ |

| Manway | ✓ | ✓ | ✓ | ✓ |

| Purge Fan | ✓ | ✓ | ✓ | ✓ |

| Quick-Clamps | ✓ | ✓ | ✓ | ✓ |

| UV Sight Tube | ✓ | ✓ | ✓ | ✓ |

| Welded Flange Nuts | ✓ | ✓ | ✓ | ✓ |

| XFMR (Transformer Bracket) | ✓ | ✓ | ✓ | ✓ |

| Cam Lock | ✓ | ✓ | ✓ | ✓ |

| Ignition Module Bracket | ✓ | ✓ | ✓ | ✓ |

6” x 6” Access

Enables easy access to internal piping, main burner, and pilot assemblies.

Lifting Lugs

Provide additional safety and stability with transporting, mounting, or securing the burner. Recommended when mounted more than 4 ft from the ground.

Manway

Manway covers are attached by nuts & bolts, providing easy access to internal components.

Purge Fan

Purge fans push air through the firetube and stack, eliminating residual gas.

Transformer Bracket (XFMR)

Transformer Brackets are made to mount inside the housing.

Ignition Module Bracket

Ignition module brackets securely mount burner management systems for reliable installation.

Quick-Clamps

Provides technicians with ease of access to burner internals. Quick-clamps are welded to the housing for seamless maintenance.

UV Sight Tube

Enables automatic flame monitoring for the burner.

Welded Flange Nuts

Aluminum nuts welded inside the housing for ease of mounting and removing the flame arrestor.

Natural Draft Burner Add-On Options

Options that are produced and attached as a separate part to the natural draft burner.

| Add-On | O-Type | Hinge Type | Box Type | Side Mount |

|---|---|---|---|---|

| Companion Flange | ✓ | ✓ | ✓ | ✓ |

| Extension Nipples | ✓ | ✓ | ✓ | ✓ |

| Extension Spool | ✓ | ✓ | ✓ | ✓ |

| Gasket | ✓ | ✓ | ✓ | ✓ |

| Manual Secondary Air Control Spool | ✓ | ✓ | ✓ | ✓ |

| Return Flu Gas | ✓ | ✓ | ✓ | ✓ |

| Threaded Vent Arrestor | ✓ | ✓ | ✓ | ✓ |

| Transformer Bracket | ✓ | ✓ | ✓ | ✓ |

| Ignition Module Bracket | ✓ | ✓ | ✓ | ✓ |

Companion Flange

Mounting flange adapter that connects the burner flange to unique customer requirements.

Extension Nipple

A custom threaded pipe to extend the nozzle/flame into the firetube to the proper and safe depth. Recommended when the nozzle is not placed within the bath solution (4" - 6").

Extension Spool

A mounting spool used to extend the flame arrestor past an obstruction. Recommended when the stack overhang exceeds the standard or when retrofitting the current unit.

Manual Secondary Air Control Spool

Control secondary airflow going into the firetube. Aimed at retaining heat in the firetube and reducing cycle times.

Return Flue Gas

Ideal for units that have the intention of returning flue gas for reuse. Also recommended for extreme weather conditions.

Threaded Vent Arrestor

Designed for end-of-line vertical venting, this arrestor enables unrestricted airflow while providing flame protection for storage tanks and atmospheric vent lines. Ideal for low-pressure systems, it prevents flame ingress without impeding normal breathing and venting operations.

Gasket

Recommended for all flange connections. The gasket provides a seamless seal aimed at preventing air or liquid from entering or exiting the flange connection.

Product Literature & Resources

Technical Documents

Product Specifications

Complete technical specifications for all burner types and configurations

Installation Manual

Step-by-step installation guidelines and safety procedures

Request for Quote

Burner Management System RFQ Form

Download and complete this form to submit your burner system requirements for quotation

Need More Information?

Our team is ready to help you select the right natural draft burner configuration for your application.

Phone:

(403) 230-3600

Email:

sales@zirco.ca

Frequently Asked Questions

What is the BTU range of natural draft burners?

expand_more

Our natural draft burners offer BTU ranges from 50,000 to 15,000,000 BTU/hr, with multiple configurations available to match specific application requirements.

What burner types are available?

expand_more

We offer O-Type, Hinge Type, Box Type, and Side Mount configurations. Each type can be customized with various design options including standard, reduced noise, low noise, air control, and elevated air supply designs.

What enhancement options are available?

expand_more

Available enhancements include 6x6 access ports, lifting lugs, manway covers, purge fans, quick-clamps, UV sight tubes, welded flange nuts, transformer brackets, ignition module brackets, and cam lock systems.

What add-on accessories can be included?

expand_more

Add-on options include companion flanges, extension nipples, extension spools, gaskets, manual secondary air control spools, return flue gas systems, threaded vent arrestors, and mounting brackets.

What is the difference between Reduced Noise and Low Noise

designs?

expand_more

Reduced Noise is partially insulated for cost-effectiveness when extreme noise reduction is not required. Low Noise is fully insulated with a baffle plate for maximum noise reduction, ideal when the operational site is near local communities.

Which burner type is best for my application?

expand_more

O-Type: Best for general purpose applications with standard firetube configurations.

Hinge Type: Ideal when frequent maintenance access is required - hinged design allows easy removal.

Box Type: Designed for space-constrained installations where vertical clearance is limited.

Side Mount: Perfect for applications requiring side-entry burner installation.

Do I need an Elevated Air Supply design?

expand_more

Elevated Air Supply designs are recommended when combustion air must be drawn from above grade level to avoid contaminated air at ground level. This is common in facilities with nearby exhaust sources, heavy vehicle traffic, or processes that generate fumes. ZIRCO can assess your site conditions and recommend the appropriate configuration.

What is the lead time for Natural Draft Burners?

expand_more

Standard configurations typically ship within 2-4 weeks. Custom or complex configurations may require 4-6 weeks. ZIRCO maintains stock of common burner types in Calgary for immediate delivery across Western Canada. Contact us for current availability and delivery estimates for your specific requirements.

Ready to Serve Your Industry?

Contact our team today to discuss how ZIRCO can provide specialized solutions for your industry needs with expertise spanning over 40 years of service across Western Canada.