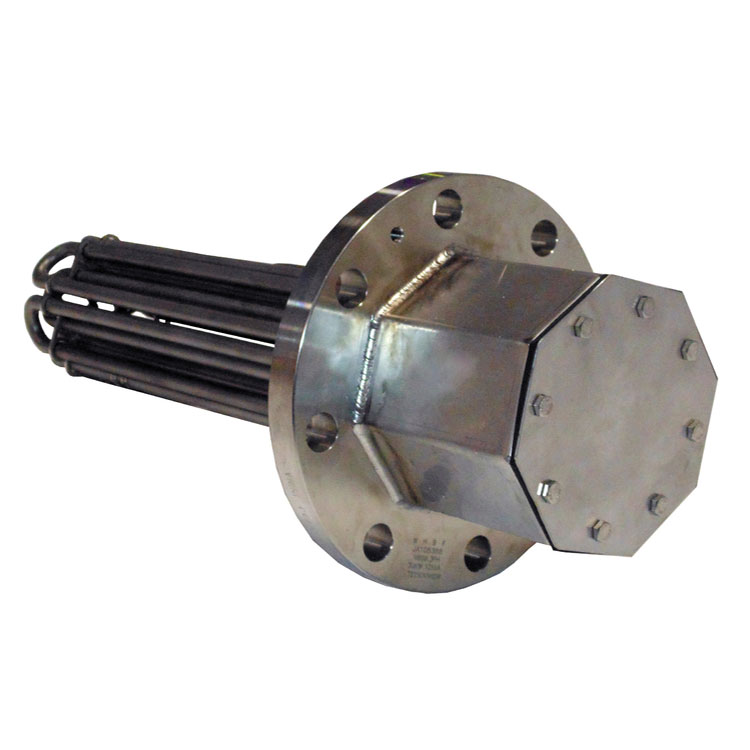

Non-Hazardous Flanged Immersion Heaters

Non-Hazardous Flanged Immersion Heaters Overview

ZIRCO is proud to distribute INDEECO non-hazardous flanged immersion heaters (ESI series) as the official representative for Western Canada. The ESI (Easiest Installation) series features a uniquely designed enclosure that simplifies mounting and wiring, reducing installation time and labor costs for general purpose heating applications.

These versatile heaters are ideal for applications where explosion-proof enclosures are not required. With wattage capacities up to 2 MW, watt densities up to 100 w/in², and process temperatures up to 1,200°F, the ESI series provides reliable heating solutions for water, oils, gases, and chemical baths. Available in NEMA 1 general purpose or NEMA 4/4X weatherproof enclosures for indoor or outdoor use.

Built by INDEECO with over 90 years of American manufacturing experience, these heaters are cCSAus certified and UL Recognized for safety and compliance. Backed by INDEECO's FastTrack shipping program, ZIRCO can deliver these heaters quickly to Western Canada industries. Our expert team provides application support to help you select the right configuration for your general purpose heating requirements.

Why Choose INDEECO Non-Hazardous Flanged Immersion Heaters?

Easiest Installation Design

ESI series features a uniquely designed enclosure that simplifies mounting and wiring, significantly reducing installation time and labor costs. The streamlined design makes field installation faster and more efficient.

FastTrack Shipping Available

Quick delivery available through INDEECO's FastTrack shipping program, getting your heaters to you when you need them most. Reduced lead times for urgent applications throughout Western Canada.

Multiple Enclosure Options

Available in NEMA 1 general purpose enclosures for indoor use or NEMA 4/4X weatherproof enclosures for outdoor and corrosive environments. Flexibility to match your application requirements.

Up to 2 MW Capacity

Powerful heating capacity up to 2 megawatts with watt densities up to 100 w/in², suitable for a wide range of industrial applications requiring substantial thermal output in general purpose environments.

High Temperature Capability

Handle process temperatures up to 1,200°F (649°C) with various sheath material options including copper, steel, stainless steel, Incoloy®, and Inconel® for different application requirements.

Flange Sizes Up to 36"

Available with flange sizes from 3" to 36" in various materials including carbon steel, stainless steel, and other alloys. ANSI B16.5 class 150 or 300 flange ratings available.

Technical Specifications

Standard Features

| Feature | Specification |

|---|---|

| Series | ESI (Easiest Installation) |

| Wattage Capacity | Up to 2 megawatts |

| Watt Density | Up to 100 w/in² |

| Voltage Range | 120V to 600V, single or three-phase |

| Process Temperature | Up to 1,200°F (649°C) |

| Flange Size Range | 3" to 36" diameter |

| Flange Rating | ANSI B16.5 class 150 or class 300 |

| Flange Materials | Carbon steel, 304/304L or 316/316L stainless steel |

| Element Sheath Materials | Copper, steel, 304 SST, 316 SST, 321 SST, Incoloy® 800, Incoloy® 840, Inconel®, and other alloys |

| Enclosure Options | NEMA 1 (general purpose), NEMA 4/4X (weatherproof) |

| Certifications | cCSAus certified, UL Recognized |

| Moisture Protection | Epoxy or RTV sealed heating elements to prevent moisture absorption |

| Electrical Connections | Stainless steel welded bussing to eliminate loose connections |

| Element Support | Heavy duty design with element support spacers on 24" centers |

| Lifting Features | Lifting lugs for heaters 4" and larger |

Optional Features & Accessories

| Option | Description |

|---|---|

| Extended Terminal Box | Provided when necessary to allow for cooler operation of the terminal box. This allows the heating elements to be sealed with epoxy or RTV and for the customer to provide incoming wire with a much lower insulation temperature rating |

| ASME Certification | The heater can be supplied in accordance with ASME section VIII Div. 1 U-Part stamped and certified |

| PED Compliance | The heater can be supplied with materials and welding procedures in compliance with the European Pressure Equipment Directive (2014/68/EU) |

| NACE Compliance | The heater can be supplied with materials, welds and their heat affected zones with hardness testing values in compliance with ANSI/NACE MR0175/ISO15156 |

| Thermostats | Bulb and capillary pilot duty or load carrying thermostats can be provided to control the heater. The thermostat bulb can be installed in a thermowell to sense process or element sheath temperature |

| Thermocouples | Type J or K thermocouples can be provided to monitor the process or element sheath temperatures. Thermocouples provided with a ceramic wafer head and screw terminals for ease of wiring. Alternate type E or T available |

| Hermetically Sealed Element Terminations | A ceramic to metal soldered seal can be provided to eliminate the possibility of moisture from entering the heating element |

| Removable Bussing | Allows troubleshooting and isolation of a failed heating element |

| Cross-Baffle | Construction utilizes alternating half baffles spaced closely to cause increased flow velocity across the heating elements to allow better heat transfer from the elements to the fluid |

| Add Support Rods | Support rods can be added to shorter heaters with high flow to keep the element support spacers in place (for flanges with length less than 30") |

| Larger Heater Circuits | Heater circuits for greater than 48A per circuit available |

| Heavy Wall Pipe Design | Element bundles with smaller outside diameter can be provided for any flange size requested |

| Pickle and Passivate | A chemical treatment in nitric acid can be performed to remove free iron from the outer surface of stainless steel for applications sensitive to contaminants |

| Electro-Polish | Is a process similar to plating using cathode and anode reactions but material is removed rather than added to the heater surfaces in order to provide a clean and bright finish |

| Alternative Materials | Other element sheath and flange materials available upon request |

| Higher Flange Ratings | Flange ratings greater than class 300 are available upon request |

Typical Applications

- Water heating and storage tanks

- Rinse tanks and cleaning systems

- Oil heating and lubrication systems

- Gas heating applications

- Chemical bath heating

- Plating tanks and metal finishing

- Cleaning and degreasing tanks

- Industrial process heating

- Food processing equipment

- Pharmaceutical process heating

Design & Installation Considerations

Non-hazardous flanged immersion heaters (ESI series) are designed for general purpose applications where explosion-proof enclosures are not required. The Easiest Installation design features a uniquely engineered enclosure that simplifies mounting and wiring, making installation faster and more efficient. These heaters are ideal for indoor use with NEMA 1 enclosures or outdoor/corrosive environments with NEMA 4/4X weatherproof enclosures.

Material selection is crucial for corrosion resistance and compatibility with the heated medium. Consider the chemical properties, operating temperature, and potential for corrosion when selecting element sheath and flange materials. The standard carbon steel flange is suitable for many applications, but stainless steel options (304/316) provide superior corrosion resistance for aggressive environments.

Proper mounting and support are essential for long-term reliability, especially for heaters with long immersed lengths. The heavy-duty design with element support spacers prevents element sagging and ensures consistent fluid flow around the heating elements. ZIRCO provides expert application support for Western Canada industries, helping you select the right wattage, watt density, material combination, and optional features for your specific general purpose heating requirements.

What Is a Non-Hazardous Flanged Immersion Heater?

A non-hazardous flanged immersion heater is an electric heating device designed for general purpose applications where explosion-proof enclosures are not required. These heaters are ideal for heating fluids and gases in tanks, vessels, and in-line heating applications in non-hazardous environments. The ESI (Easiest Installation) series from INDEECO features a streamlined enclosure design that simplifies installation while maintaining robust performance and reliability.

The flanged mounting design provides a secure connection to tanks, vessels, or piping systems, while multiple heating elements deliver substantial thermal input for medium to large-volume heating applications. Available with NEMA 1 general purpose enclosures for indoor use or NEMA 4/4X weatherproof enclosures for outdoor and corrosive environments, these heaters offer versatility for a wide range of industrial applications.

INDEECO non-hazardous flanged immersion heaters leverage over 90 years of American manufacturing experience to deliver efficient, reliable, and cost-effective heating solutions. With wattages up to 2 MW, watt densities up to 100 w/in², and process temperatures up to 1,200°F, these heaters provide excellent performance for water heating, oil heating, chemical baths, plating tanks, and many other general purpose industrial applications throughout Western Canada.

Product Literature & Resources

Technical Documents

General Specifications Sheet

Complete product specifications and technical parameters

Dimensional Drawings

Detailed dimensions and technical drawings

Installation Instructions

Step-by-step installation and mounting guidelines

Complete Technical Manual

Comprehensive technical documentation (1.5MB)

Product Catalog

Full product catalog with selection guide

Request for Quote

Request for Quote (RFQ) Form

Download and complete this form to submit your immersion heater requirements for quotation

Contact for More Information

ZIRCO is the authorized Western Canada representative for INDEECO non-hazardous flanged immersion heaters (ESI series). Contact our team for:

- Heater selection and sizing assistance

- Technical specifications and support

- Application engineering guidance

- Material compatibility recommendations

- Quotations and FastTrack shipping information

- After-sales service and support

- Custom configuration options

- Wattage and voltage recommendations

Ready to Optimize Your General Purpose Heating Solution?

Contact our team today to discuss how INDEECO non-hazardous flanged immersion heaters (ESI series) can provide efficient, reliable, and cost-effective heating for your general purpose applications. ZIRCO provides expert support for Western Canada's industrial sectors with FastTrack shipping available for quick delivery.