Oil Tank Jet Mixers

Tank Mixing Overview

Transvac Tank Jet Mixers are mass momentum exchange devices that use pressurized liquid energy from an external recirculating pump to entrain, mix, and pump fluids. As static devices with no moving parts, they provide unmatched reliability and require zero maintenance, making them ideal for oil tank mixing applications.

How Jet Mixers Work: A high-pressure motive fluid is pumped through a nozzle, creating a high-velocity jet that entrains surrounding tank contents. This entrained fluid is mixed with the motive stream in the mixer throat, and the combined discharge creates a vigorous mixing action throughout the tank.

Key Benefits: Unlike mechanical agitators with motors, gearboxes, and rotating impellers, Transvac jet mixers have no components to wear, fail, or replace. This eliminates maintenance costs, reduces downtime, and provides continuous reliable operation. Available in a wide range of materials to suit various applications.

Why Choose Jet Mixer Technology?

No Moving Parts

Static design with no motors, gearboxes, or rotating impellers. Zero maintenance means minimal downtime and lower lifecycle costs.

Mass Momentum Exchange

Efficient mixing through momentum transfer. Uses existing pump energy - no additional power required beyond recirculation pump.

Unmatched Reliability

No components to wear, fail, or replace. Operates continuously without scheduled maintenance, ideal for critical applications.

Technical Specifications & Design

How Jet Mixers Work

Transvac Tank Jet Mixers operate on the venturi principle. A high-pressure motive liquid is pumped through a converging-diverging nozzle, converting pressure energy into kinetic energy and creating a high-velocity jet. This jet entrains surrounding fluid from the tank, drawing it through the mixer's suction chamber.

The mixed fluids then pass through a diffuser section where kinetic energy is converted back into pressure, discharging a high-volume, well-mixed stream back into the tank. Multiple mixers can be strategically positioned to ensure complete tank homogenization.

Operating Principle

Transvac jet mixers use venturi action to create efficient tank mixing through momentum transfer

Design Capabilities

| Feature | Specification |

|---|---|

| Operating Principle | Venturi ejector / Mass momentum exchange |

| Motive Fluid | Process liquid recirculated by external pump |

| Moving Parts | None - static device |

| Maintenance Requirement | Zero scheduled maintenance |

| Construction Materials | Carbon steel, stainless steel, duplex, exotic alloys available |

| Design Options | Single or multiple nozzle configurations available |

| Sizing Method | CFD analysis available for optimized mixing |

| Application Range | Any fluid handleable by centrifugal pump |

Construction Materials

Transvac Tank Jet Mixers are available in a wide range of materials to suit various applications and fluid compatibilities:

Standard Materials

- • Carbon steel

- • 304/316 Stainless steel

- • Duplex stainless steel

Exotic Alloys

- • Hastelloy

- • Monel

- • Titanium

- • Specialty alloys on request

Tank Mixing Applications

Transvac Tank Jet Mixers have been successfully adopted for in-tank mixing throughout diverse industries, providing reliable maintenance-free operation where traditional mechanical agitators face challenges.

Oil & Gas Storage Tanks

Maintain product homogeneity in crude oil, diesel, gasoline, and jet fuel storage tanks. Prevent stratification, ensure uniform temperature distribution, and eliminate sediment buildup. Ideal for remote locations where maintenance access is limited.

Chemical Processing Tanks

Mix and maintain homogeneity of chemicals, solvents, and process fluids. Suitable for aggressive chemicals with exotic alloy construction options. Eliminates seal leaks and bearing failures common with mechanical agitators.

Water & Wastewater Treatment

Maintain suspension of solids, prevent settling, and ensure chemical mixing in treatment tanks. Used in potable water storage, wastewater equalization tanks, and sludge storage. No electrical components required in hazardous areas.

Pharmaceutical & Food Industry

CIP (Clean-in-Place) applications, tank sanitization, and product mixing. Hygienic design with no lubrication requirements or contamination risks. Polished stainless steel construction meets sanitary standards.

Western Canada Applications

ZIRCO provides Transvac Tank Jet Mixer solutions specifically tailored for Western Canada's oil and gas industry, including:

- Oil Storage Terminals: Crude oil, diesel, and gasoline tank homogenization

- Upstream Facilities: Production tank mixing and separator inlet conditioning

- Refinery Tank Farms: Product blending and uniformity maintenance in large storage tanks

- Remote Field Locations: Maintenance-free mixing where service access is limited

- Hazardous Areas: Intrinsically safe operation without electrical components in classified areas

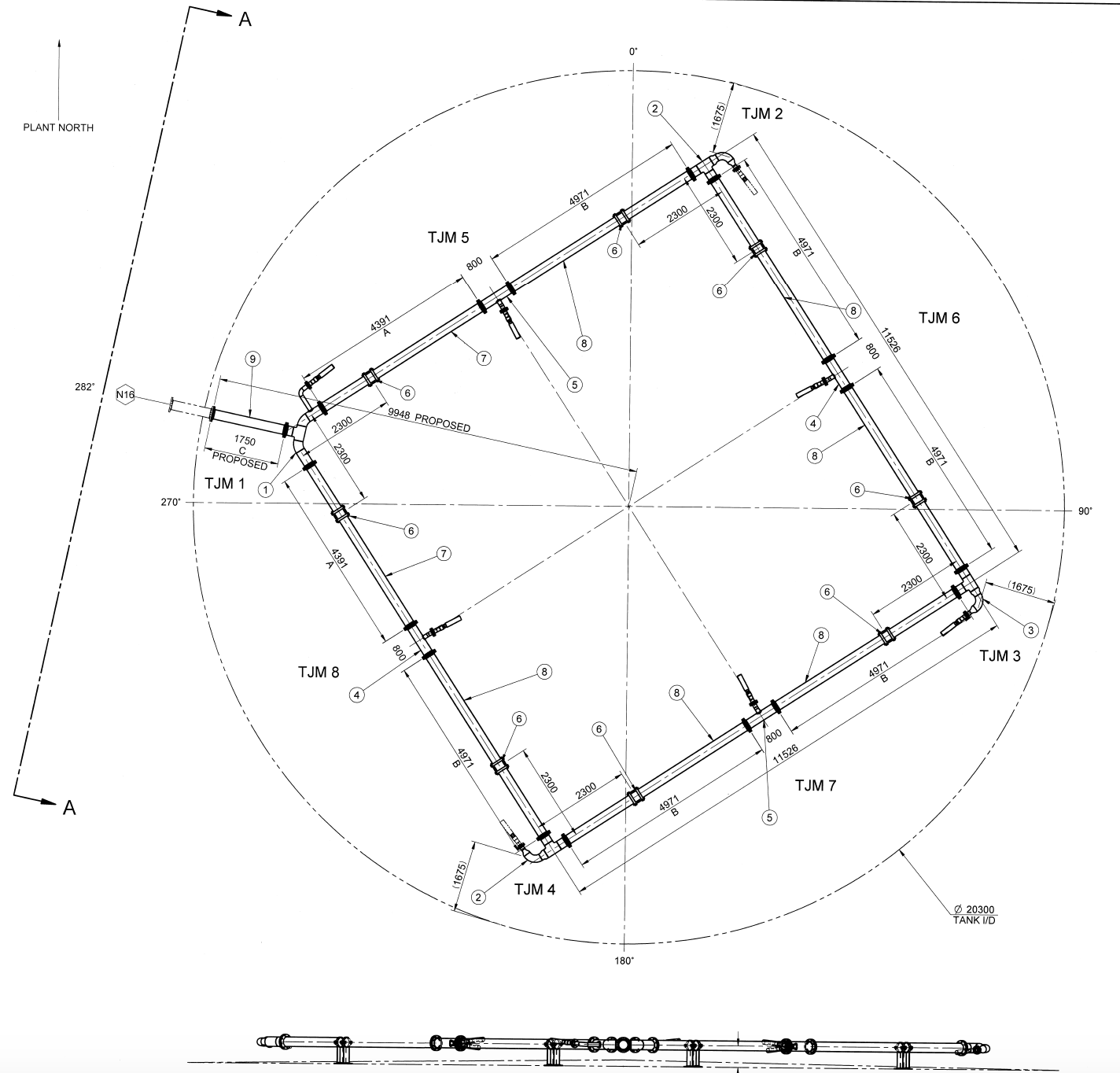

CFD Analysis for Perfect Tank Mixing

Transvac utilizes Computational Fluid Dynamics (CFD) analysis to optimize jet mixer placement and performance for each specific tank application. This ensures complete mixing with minimal energy input.

CFD modeling predicts flow patterns, mixing times, and dead zones, allowing Transvac to design the most efficient mixer configuration for your tank geometry and fluid properties. ZIRCO can provide CFD analysis support for Western Canada projects.

Product Literature & Resources

Technical Documents

Contact for More Information

ZIRCO is the authorized Western Canada representative for Transvac Tank Jet Mixers. Contact our team for:

- Technical specifications and sizing

- CFD analysis and mixer placement optimization

- Application engineering support

- Quotations and delivery information

- After-sales service and support

Ready to Eliminate Mixer Maintenance?

Contact our team today to discuss how Transvac Tank Jet Mixers can provide reliable, maintenance-free tank mixing for your oil and gas operations. ZIRCO provides expert support for Western Canada applications.