Production Boosting

Enhanced Recovery & Production Boosting

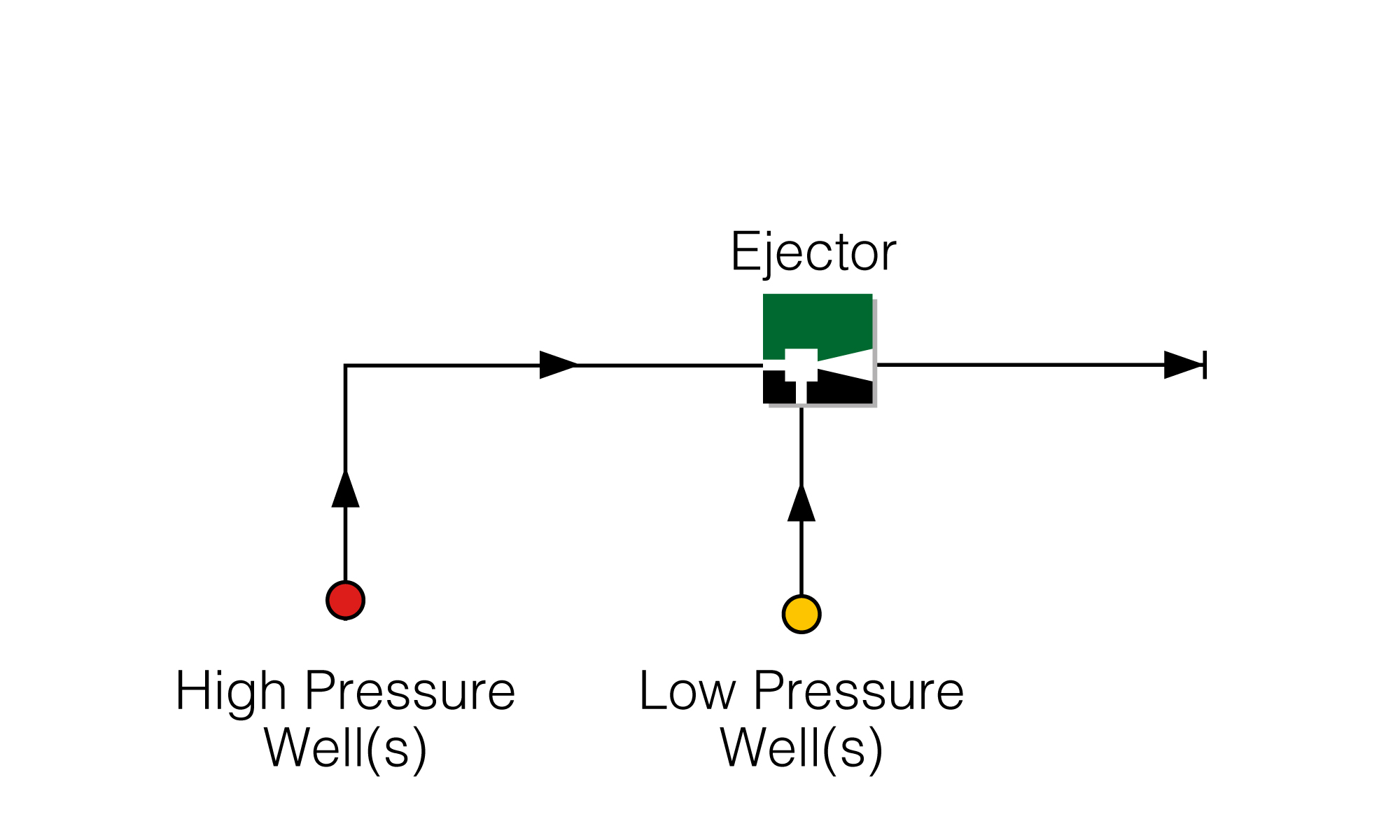

Ejectors are an effective tool to increase production, enhance recovery, and extend the life of mature fields. This is achieved by lowering the back-pressure on a well (or multiple wells) imposed by downstream pipeline and process equipment. ZIRCO delivers these proven Transvac solutions to Western Canada's oil and gas operators.

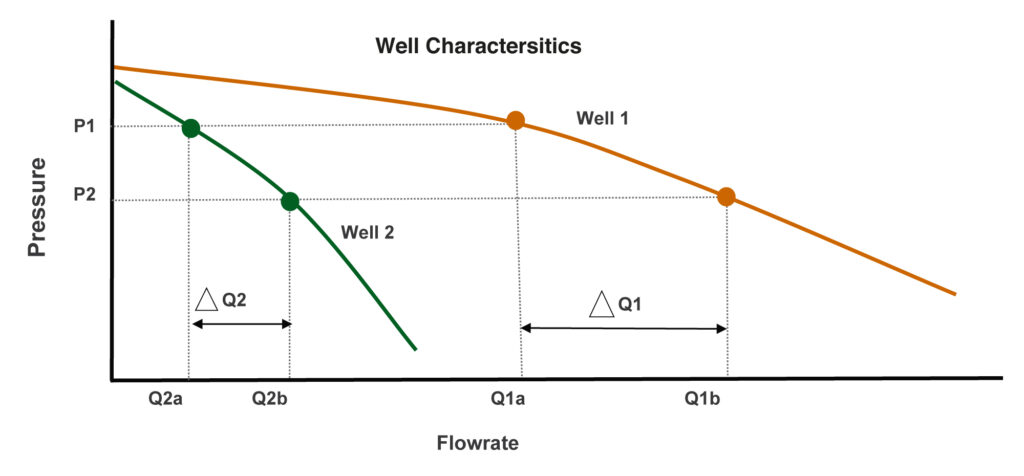

How It Works: The reduction in flowing wellhead pressure (FWHP) results in increased production. In many cases, this also stabilizes production and improves the flow regime of fluids through the wellbore. Each well has unique characteristics, and Transvac's ejector technology can be optimized for your specific field conditions.

The Economics: Even with fast-declining high pressure wells, the economics of ejector projects are compelling. The energy is used efficiently and effectively to boost production from low-pressure wells, providing significant payback from extra production—all with zero operating costs and no maintenance requirements.

Why Choose Ejector Technology for Production Boosting?

Zero Operating Costs

Ejectors are static, pipework-based compressors with no moving parts. They utilize otherwise-wasted energy from high-pressure streams, requiring zero maintenance and having no carbon footprint.

Fast-Track Installation

Boost production in as little as 8 weeks. Compact size allows for retrofit into existing facilities, including offshore platforms where space and weight restrictions apply.

Universal Design

Future-proof your investment with Transvac's Universal Design Ejectors. Changeable internals allow the ejector to adapt as well pressures decline, and can be relocated to new sites for repeated use.

How Production Boosting Ejectors Work

Factors Affecting Production Increase

The increase in production depends on two main factors:

- The Productivity Index (PI) of the LP wells - The PI value is provided by the operator, but an accurate value at the reduced FWHP may not be available. The only way to establish the PI at reduced pressure is to test the well using a test separator.

- The amount of reduction in FWHP - The achievable drop depends on factors such as the HP/LP pressure ratio, flow ratio across the ejector, type of motive flow (gas or liquid), and the amount of liquids in LP gas.

Identifying a Motive Stream

Ejectors can be driven by various high-pressure streams available at your facility:

vertical_align_top High Pressure Wells

Newly-drilled wells often operate at elevated pressure. Early in the well's life, this energy can be captured and used by an ejector rather than being wasted or throttled back. Some fields operate with both high and low-pressure tie-backs, where the ejector can boost LP wells into the low-pressure line.

block Choked Wells

Rather than wasting pressure energy across a choke valve, the ejector nozzle becomes, in effect, a choke and uses the energy usefully. This technique can revive dead or shut-in wells by using energy from choked high-pressure wells.

compress Compressors in Recycle

As production declines, many gas compressors operate inefficiently in constant recycle conditions. The energy wasted across the recycle valve can drive an ejector to lower pressure on LP wells, boosting production and sometimes bringing dead wells back to life—at no energy cost.

water_drop High Pressure Water

Transvac's advances in liquid-motivated ejectors enable very high compression ratios. Injection water or produced water can motivate the ejector, using existing facilities—ideal for brownfield developments.

propane High Pressure Oil or Gas

Similar to using high-pressure water, oil or gas can effectively drive an ejector. High-pressure gas can be taken from a separator outlet, compressor discharge, or export gas compressor—including gas lift systems.

Advantages of Ejectors for Enhanced Recovery

Future-Proof with Universal Design

Transvac's Universal Design Ejectors provide an extended operating window. The ejector "follows" and adapts to the high-pressure well curve as it changes over time, through use of different sets of ejector "internals."

Key Benefits of Universal Design:

- New ejector internals can be fitted as well pressures decline to maximise production

- New internals can be fitted in less than one shift

- Ejector has no running costs—it utilises motive gas energy which is normally wasted across a choke valve

- Requires no maintenance and produces no emissions

- Universal design allows manufacture of new ejector internals to be delayed until HP well is drilled, reducing project risk

- Extra gas produced from shut-in wells

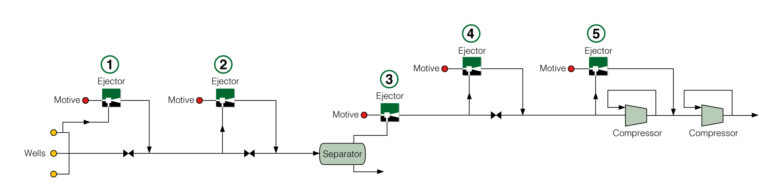

Typical Ejector Locations for Production Boosting

Ejectors can be installed at various points in your production system to boost production. Multiple ejector opportunities can be implemented simultaneously, and ejectors can work alongside other EOR (Enhanced Oil Recovery) techniques such as gas lift or ESPs.

Option 1: One Well

An ejector is used to assist a single well. This could include restarting a dead well, kick-starting/well kick-off, or deliquification. The ejector reduces wellhead pressure to stimulate production and then boosts the pressure up to satisfy downstream line pressure requirements.

Option 2: Multiple Wells

An ejector is used to assist multiple wells from a manifold. This application includes restarting dead wells, kick-starting, or deliquification. The ejector reduces manifold pressure to stimulate upstream well production, then recompresses and discharges at the required line pressure.

Option 3: Reduce Separator Pressure

An ejector is used to reduce the separator operating pressure by entraining the gas outlet stream. This reduces back-pressure on any upstream wells, stimulating both oil and gas production. For gas fields, the reduced pressure also increases pipeline velocity, which helps clear liquid slugs and condensate to stabilize production.

Option 4: 1st Stage Compression

An ejector acts as a new 1st-stage compressor, offering a lower inlet pressure than the original compression system. This technique reduces back-pressure on upstream wells or production equipment, stimulating extra production. The ejector then compresses the stream and discharges it at the required (or improved) compressor inlet pressure.

Option 5: De-bottleneck a Compressor

LP compressors can become bottlenecks for production. An ejector provides additional compression capacity, discharging to either an inter-stage pressure or compressor outlet pressure. In some cases, the ejector can entirely replace an LP compressor, eliminating maintenance and OPEX.

LJC Package Solution

No Motive Stream Available? Where an existing motive stream is not available, Transvac can provide a "Liquid Jet Compressor" (LJC) Recirculation Package. This solution utilizes a high-pressure pump to provide suitable motive to an LJC ejector which entrains and compresses gas.

The discharge is multi-phase (gas and liquid), so the package includes a separator to allow the process gas stream to be discharged to downstream processing. The water/liquid outlet is recirculated back to the pump suction, meaning the solution does not require constant fluid feed as it is recycled.

Product Literature & Resources

Technical Documents

Request for Quote

Request for Quote (RFQ) Form

Download and complete this form to submit your ejector requirements for quotation

Contact for More Information

ZIRCO is the authorized Western Canada representative for Transvac Production Boosting Ejectors. Contact our team for:

- Technical specifications and sizing

- Application engineering support

- Quotations and delivery information

- After-sales service and support

Ready to Boost Your Production?

Contact our team today to discuss how Transvac Production Boosting Ejectors can increase production, extend field life, and reduce operating costs at your Western Canada operation. ZIRCO provides expert support from project evaluation through installation and beyond.