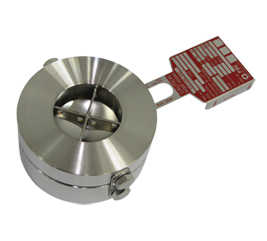

KSRRK Rupture Disc & Explosion Panel

KSRRK Rupture Disc & Explosion Panel Overview

ZIRCO is proud to distribute KSPC KSRRK Rupture Discs & Explosion Panels as the official representative for Western Canada. These fail-safe pressure relief devices provide critical protection for storage tanks and process equipment when primary safety devices are compromised or during extreme pressure rise scenarios. Designed as single-use emergency relief devices that rupture at preset pressures to prevent catastrophic equipment failure and ensure personnel safety.

The KSRRK series is specifically engineered for emergency pressure relief applications including fire exposure, process upsets, and abrupt pressure rise events. When normal pressure relief devices are insufficient or damaged, the rupture disc provides reliable fail-safe protection by bursting at a precisely calculated pressure, allowing rapid pressure evacuation and protecting the structural integrity of storage tanks, reactors, and process vessels throughout Western Canada's industrial facilities.

Constructed from premium materials including stainless steel, Hastelloy, Inconel, and special alloys, these devices handle corrosive oils, harsh chemical environments, and materials prone to synthetic reactions. Suitable for extreme temperature environments from cryogenic applications to high-heat processes. The rupture disc design prevents oil leakage and environmental contamination while providing dependable emergency protection for oil sands storage tanks, petrochemical reactors, gas processing plants, mining operations, and chemical storage facilities across Alberta, British Columbia, and Saskatchewan.

Why Choose KSRRK Rupture Discs & Explosion Panels?

Fail-Safe Protection

Provides reliable pressure relief when primary safety devices are damaged, compromised, or insufficient, ensuring equipment protection during emergency scenarios.

Abrupt Pressure Relief

Designed for sudden pressure rise scenarios including fire exposure, process upsets, and emergency conditions requiring instant pressure relief.

Corrosion Resistant

Handles corrosive oils, harsh chemical environments, and aggressive process fluids with specialized material construction for long-term reliability.

Extreme Temperature Capability

Suitable for extreme temperature environments from cryogenic applications to high-heat processes, maintaining performance integrity across wide temperature ranges.

Leak Prevention

Prevents oil leakage and environmental contamination with hermetic seal design until rupture pressure is reached, protecting product quality and environment.

Wide Application Range

Suitable for materials prone to synthetic reactions and diverse industrial processes, providing versatile emergency protection solutions.

Technical Specifications

KSRRK Rupture Disc & Explosion Panel Specifications

| Specification | Details |

|---|---|

| Model | KSRRK (KSPC Rupture Disc & Explosion Panel) |

| Type | Fail-Safe Emergency Pressure Relief Device (Single-Use) |

| Burst Pressure Range | 0.1 bar to 10+ bar (customizable for specific application requirements) |

| Operating Temperature Range | -50°C to +500°C+ (depending on material selection) |

| Available Sizes | 25mm to 600mm+ diameter (standard and custom sizes) |

| Design Standards | ASME Section VIII, API 2000, ISO 4126 compliant |

| Body Materials | Stainless Steel (304, 316), Hastelloy, Inconel, Monel, Nickel, Graphite, and specialty alloys |

| Construction | Single-use design with precision-calculated burst pressure, hermetically sealed until activation |

Materials Available

| Material | Applications |

|---|---|

| Stainless Steel 304 | General industrial applications, corrosive environments, oil & gas storage |

| Stainless Steel 316 | Highly corrosive environments, chemical processing, petrochemical applications |

| Hastelloy | Extreme corrosive environments, high-temperature chemical processes |

| Inconel | High-temperature applications, oxidizing environments, extreme pressure conditions |

| Monel | Hydrofluoric acid service, marine environments, corrosive chemical applications |

| Nickel | Caustic environments, high-temperature alkaline applications |

| Graphite | Corrosive acid environments, high-temperature applications, aggressive chemical service |

Design & Performance Characteristics

| Characteristic | Description |

|---|---|

| Fail-Safe Operation | Provides reliable pressure relief when primary safety devices fail or are overwhelmed |

| Single-Use Design | Ruptures at preset pressure and requires replacement after activation (no reclosing) |

| Precision Burst Pressure | Manufactured to tight tolerances ensuring activation at specified pressure (typically ±5% or better) |

| Hermetic Seal | Maintains leak-tight seal until burst pressure is reached, preventing product loss |

| Zero Maintenance | No moving parts or mechanical components to inspect or maintain until activation |

| Instant Response | Reacts immediately when pressure exceeds burst rating, unlike spring-loaded valves with response time delays |

Typical Applications

- Emergency pressure relief for storage tanks during fire exposure scenarios

- Protection when fixtures damage primary safety relief materials

- Abrupt pressure rise scenarios in reactors and process vessels

- Corrosive oil and chemical storage requiring specialized materials

- Materials prone to synthetic reactions or unstable chemical processes

- Extreme temperature environments from cryogenic to high-heat

- Oil sands storage tanks (Fort McMurray, Alberta)

- Petrochemical reactors (Edmonton, Redwater)

- Gas processing plants (Alberta, British Columbia)

- Mining operations (Saskatchewan)

- Chemical storage facilities throughout Western Canada

- Dust collectors and explosion venting systems

- Pipeline protection systems

Installation Requirements

The KSRRK rupture disc must be installed in accordance with ASME Section VIII, API 2000, and local applicable codes. Key installation considerations:

- Install upstream or downstream of primary relief valve as backup protection

- Ensure proper orientation as specified for the rupture disc type (forward-acting, reverse-acting, or composite)

- Verify holder/housing compatibility with process connections (flanges, threaded, sanitary fittings)

- Select appropriate material for compatibility with stored product and environmental conditions

- Coordinate burst pressure rating with vessel MAWP (Maximum Allowable Working Pressure)

- Provide adequate discharge piping to direct relieved media to safe location

- Replace immediately after activation (single-use device, no reclosing capability)

- Regular inspection recommended to verify integrity and replace if damage or corrosion is detected

What Is a Rupture Disc?

A rupture disc (also known as a burst disc or safety disc) is a thin, specially designed membrane made of metal or graphite that is precision-engineered to rupture at a specific pressure. This fail-safe safety device provides instant pressure relief when the internal pressure exceeds the disc's rated burst pressure, protecting equipment from catastrophic failure and preventing dangerous explosions. Unlike spring-loaded relief valves, rupture discs have no moving parts and provide instantaneous response time.

Rupture discs serve as primary relief devices in many applications and as secondary backup protection when installed in series with conventional pressure relief valves. In the backup role, they provide critical protection if the primary valve fails, becomes blocked, or is overwhelmed during emergency conditions such as fire exposure. The single-use design means the disc must be replaced after activation, but this ensures complete system integrity reset with each new installation.

Rupture Disc vs. Explosion Panel: While both function on the same principle, rupture discs are typically smaller circular devices for liquid or gas service in pressure vessels and piping. Explosion panels are larger rectangular panels designed for rapid pressure relief during deflagration or explosion events in dust collectors, process vessels, and buildings. Both provide fail-safe emergency protection but are optimized for different applications.

Rupture Disc vs. Relief Valve: Relief valves are reclosing spring-loaded devices that open proportionally to overpressure and close when normal pressure is restored. Rupture discs are single-use devices that provide instantaneous, non-reclosing relief at a precise pressure. Rupture discs are often specified as backup to relief valves, for corrosive service that would damage valve internals, or when zero leakage and instant response are critical requirements.

Rupture Disc vs. Relief Valve Comparison

| Characteristic | Rupture Disc | Relief Valve |

|---|---|---|

| Operation | Single-use, ruptures at set pressure | Reclosing, reusable |

| Response Time | Instantaneous | Delayed (spring response) |

| Leakage | Zero leakage until burst | May have minor leakage |

| Maintenance | None required until activation | Regular testing and maintenance |

| Cost | Lower initial cost | Higher initial cost |

| Replacement | Required after each activation | Can be reset after activation |

| Best Application | Fail-safe backup, corrosive service, emergency relief | Primary pressure relief, reclosing required |

Contact ZIRCO for assistance determining which pressure relief strategy best suits your application.

Western Canada Industry Applications

Oil Sands Operations (Fort McMurray, Alberta)

Emergency pressure protection for bitumen storage tanks, diluent recovery systems, and upgrading process vessels. Rupture discs provide fail-safe protection during fire scenarios and process upsets in critical extraction and processing operations.

Petrochemical Facilities (Edmonton, Redwater, Joffre)

Reactor emergency relief, corrosion-resistant materials for aggressive chemical processes, and backup protection for pressure relief systems in ethylene, polyethylene, and chemical manufacturing plants.

Gas Processing Plants (Alberta, British Columbia)

Emergency relief for amine treaters, sweetening units, and dehydration systems. Specialized materials for sour gas (H2S) service and high-pressure applications ensuring personnel safety and environmental protection.

Mining & Mineral Processing (Saskatchewan)

Pressure relief for ore processing equipment, tailings systems, and chemical treatment vessels. Corrosion-resistant options for harsh mining environments and chemical processing applications.

Product Literature & Resources

Technical Documents

KSRRK Rupture Disc Catalog

Complete specifications, burst pressure ratings, material compatibility, performance data, and application guidelines for KSRRK Rupture Discs & Explosion Panels

Request for Quote

Request for Quote (RFQ) Form

Download and complete this form to submit your rupture disc requirements for quotation

Contact for More Information

ZIRCO is the authorized Western Canada representative for KSPC KSRRK Rupture Discs & Explosion Panels. Contact our team for:

- Technical specifications and burst pressure selection assistance

- Material compatibility recommendations for corrosive environments

- ASME and API code compliance consultation for pressure relief systems

- Application engineering support for emergency relief scenarios

- Rupture disc vs. relief valve system design guidance

- Western Canada industry application expertise (oil sands, petrochemical, gas processing)

- Quotations and delivery information

- After-sales support and technical assistance

Ready to Enhance Your Storage Tank Emergency Protection?

Contact our team today to discuss how KSPC KSRRK Rupture Discs & Explosion Panels can provide fail-safe emergency pressure relief for your storage tanks and process equipment. ZIRCO provides expert support for Western Canada's oil & gas, petrochemical, mining, and industrial facilities requiring reliable emergency protection solutions.